Elmendorf tearing tester

The ProTear tear strength testers from Thwing-Albert provide a rapid and precise way to evaluate the tear resistance of sheet materials including paper, textiles, roofing products, plastic film, and foils. The electronic model features a touch-screen panel that allows for a simple one-touch process to run tear tests and track data. Two different pendulums are available with various augmenting weights. The ProTear tear strength tester offers several capacity configurations. MAP4 Software can be used to evaluate the tear strength with the dynamic tear data calculated at every point of the test to allow for real-time data as the sample tears.

Application: Paper & Pulp, Textile

Property: Tearing - Tear resistance tests

Trust the Thwing-Albert Electronic ProTear to measure Elmendorf Tear Strength of a variety of materials. Thwing-Albert is the original manufacturer of the Elmendorf Tear Tester which was designed by Dr. Thwing and Mr. Armin Elmendorf. This method developed over a century ago established the industry standards used worldwide today to measure tear strength.

The ProTear provides a rapid and precise way to evaluate the tear resistance of sheet materials including paper, textiles, roofing products, plastic film, and foils.

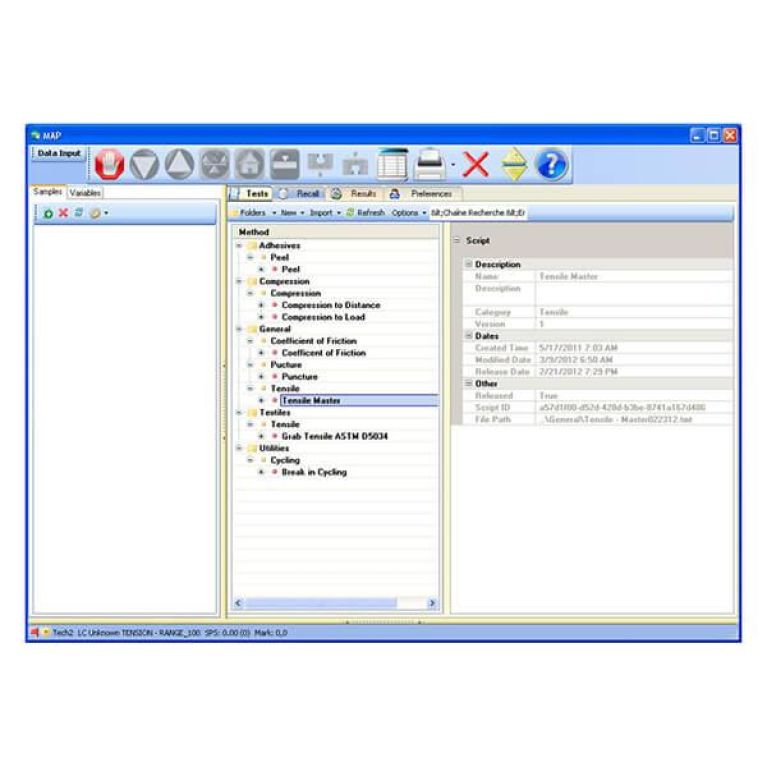

The electronic model features a touch-screen panel that allows for a simple one-touch process to run tear tests and track data. Two different pendulums are available with various augmenting weights and can be configured to meet capacities from 200g-12,800g. MAP4 Software can be used to evaluate the sample test results with dynamic tear data calculated at every point of the test to allow for real-time data as the sample tears.

- Capacity 200, 400, 800, 1600, 3200, 6400, 12,800gms

- Industry Corrugated, Cardboard, Nonwovens, Packaging, Paper, Paperboard, Plastic Film, Pulp, Textiles

- Net Weight 16.8 kg (37 lbs)

- Dimensions 483 x 398 x 578 mm [19 x 15.66 x 23 in]

- Testing Property Elmendorf Tear, Tear Strength

- List of Standards ASTM D295, ASTM D752, ASTM D4247, ASTM D1424, ASTM D1922, TAPPI T414, TAPPI T496, ISO 1974, ISO 9290, ISO 13937-1

- Accuracy 0.2% of Pendulum Capacity

- Software Available MAP4, WinWedge

- Touch-screen menu

- Toolless easy-mount pendulums and augmenting weights

- Electronic leveling sensor for accurate setup

- Configurable display for results and reporting

- MAP4 Software for advanced analysis

- Multi-Port connections for data export

- One-touch pneumatic clamping and pendulum release

The operation of the ProTear is easy —simply secure the sample in the clamps, make an initial tear and press test to release the pendulum. The tearing resistance of the material is measured via the transference of the potential energy stored in the raised pendulum to kinetic energy. A portion of this energy is absorbed during the tearing of the sample and is used as a measure of the resistance of the material to a continuing tear. The energy required to tear the sample is reported as a percentage of the pendulum capacity or force.

The Electronic ProTear calculates all test results and statistics automatically and displays them immediately. Data can be exported to a PC, directly printed or analyzed in more depth using MAP4 materials testing software.

Precision and accuracy are increased by capturing dynamic tear data in real-time digitally. The capacity can be changed quickly with easy-mount technology for pendulum installation that does not require tools. Testing capacity ranges from 200g up to 12,800g allowing for a variety of applications with one machine.

The touch-screen display allows for quick clamping and testing. Lab technicians can easily customize units of measurement and reporting styles in the menu. Other functions include data entry of sample information such as sample ID, thickness, basis weight, sample direction and number of plies being torn.

MAP4 software is available for customers that would like to run detailed reports and have access to in-depth data. A preloaded test will be available and is configured to meet the industry standards from ASTM, TAPPI, and others. The program includes a SQL Lite database. MAP4 will provide a real-time data curve at the same time as the results are being displayed.

Others also viewed

More info? Quotation?

Any questions? Don't hesitate to contact us.